Facts

- Only natural graphite has a perfect flake structure formed over millions of years.

- Due to its structure, natural graphite is smooth and soft, like a good pencil.

- Purified natural graphite is free of minerals such as quartz. Some of our competitors use artificial graphite made from electrodes scrap.

- Artificial graphite is mostly graphitized petroleum coke, produced in about 2 weeks.

- Some competitors who use natural graphite usually have no idea where the graphite comes from, which country, which mine. Often they buy from traders.

Facts

- HCC knows the complete path of the graphite (important for stable quality) and applies a special preparation process.

- HCC does not grind the graphite in ball mills or agitator ball mills to avoid impurities such as ball abrasion. Above all, to protect the structure of the graphite.

- Purified natural graphite is free of minerals such as quartz. Some of our competitors use artificial graphite made from electrodes scrap.

- From responsibility towards the environment and employees, we do not use ammonia.

- HCC has found a unique combination between the chemical additives and the manufacturing process.

Good chemistry at work!

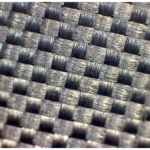

Natural graphite – flake type

The SEM image of a natural graphite flake (side view) shows thousands of layers perfectly arranged by nature. These layers

can be shifted against each other.

This gives the graphite its lubricating properties.

HCC uses only natural graphite from defined sources and monitors particle size and shape throughout the preparation process.

Natural graphite versus artificial graphite

These SEM images show the particle structure of natural and artificial graphite,* ground in the same way. Clearly visible is the rough and uneven structure of the artificial graphite. The beautiful platelet structure of the natural graphite covers the surface of the steel and gives a perfect lubrication.

Natural graphite

Artificial graphite

*Artificial graphite from unused electrode scrap.

Chemicals

Ammonia solution NH4OH.

This chemical should not be used in any lubricant.

HCC has banned this chemical.

Decomposition products during the forging process (smoke) should not be harmful to health.

Now you have the knowledge to ask your lubricant supplier critical questions. Or better yet, switch to HCC now.

Ask your supplier the following questions:

- Do you use natural or artificial graphite?

- How do you grind the graphite? (Possible answer: “That’s secret.”)

- In the case of natural graphite – Do you know the exact origin of the graphite (not the dealer)?

- Are you sure that the quality is constant?

- Is there a health risk from decomposition products?

- Why are you still using ammonia? (This question only for antiquated companies.)

Successful results – through natural products

Hexagons – the perfect structure