Surface and infrared heating systems are an alternative heating system or also a supplement to an already existing central heating system in new and old buildings. Since oil and gas heating systems have a poorer efficiency and a much worse CO2 balance, the infrared heating system is gaining more and more importance in the future.

The infrared heaters work completely differently than conventional heaters, as they emit electromagnetic waves, so-called infrared rays. This is the most optimal way to transport energy. With our dispersion all common materials can be coated. After contacting, a power source can be applied and converts it into heat radiation up to almost 100%. Thus, the energy loss of infrared heaters is much lower compared to conventional systems. The lower energy loss is mainly explained by the line resistance. The lower the resistance, the higher the efficiency.

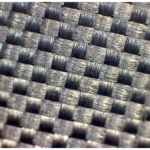

We have developed a dispersion that can be used in all areas of infrared heating. Both for impregnating fabrics, especially glass fiber fabrics, and for use as a paint coating with the inclusion of a binder.

Our dispersion has a lower resistance value compared to the state of the art.

As a result, energy consumption can be reduced and efficiency increased, as described.

We do not use carbon nanotubes (CNT) and thus take toxicological and price aspects into account.